TYPES OF HYDRAULIC CYLINDERS BY FUNCTIONING

2022-11-10

Most of you are aware that pumps deliver energy to a hydraulic system by converting mechanical energy into

hydraulic energy. But once the pump delivers that energy, do you know how it is

utilized in the hydraulic system? Well, the answer to that is the motion of the

components. The energy from the hydraulic fluid is used to move the components.

This movement is achieved by using actuators in a hydraulic system.

A hydraulic system can use various

types of actuators that convert hydraulic energy into mechanical motion. Linear

actuators convert the energy into linear mechanical motion, while rotary

actuators convert the energy into rotational motion. A hydraulic cylinder is a type of

linear actuator that converts fluid power into linear motion. This linear

motion is achieved by extending and retracting a piston rod by applying

pressure through the hydraulic fluid or oil.

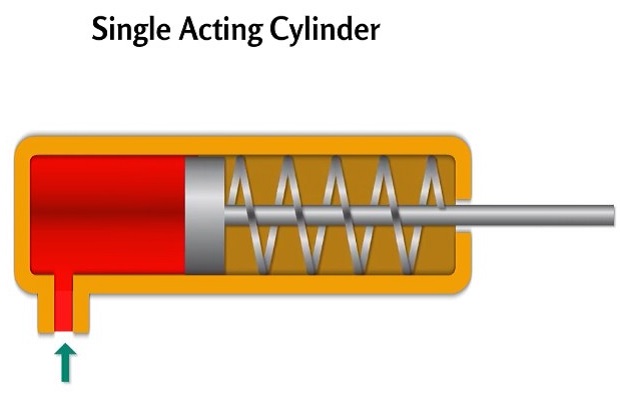

Generally, there are two types of

hydraulic cylinders based on their functions. The simplest type is called a

single acting cylinder. Just as the name suggests, in a single acting cylinder,

the pressure from hydraulic fluid can only actuate the cylinder in one

direction, either in extension or retraction. To return to the normal position,

such cylinders use a spring. A single acting cylinder has a port at one end of

the cylinder for the entry and exit of the hydraulic fluid. The cylinder

housing, also called a barrel, has a piston inside that is connected with a rod.

As the fluid enters the blank end, the rod is extended outside the cylinder from

the other end, called the rod end. In a hydraulic circuit, the components are

represented such that it clearly shows the functioning of the component without

actually showing its detailed construction. This allows for easy analysis of

the hydraulic circuit. A single acting cylinder is represented similarly to

show the functioning. One drawback of the single acting cylinder is a spring that can cause mechanical problems due to spring failure. For this reason, they are

not used in applications with large stroke length.

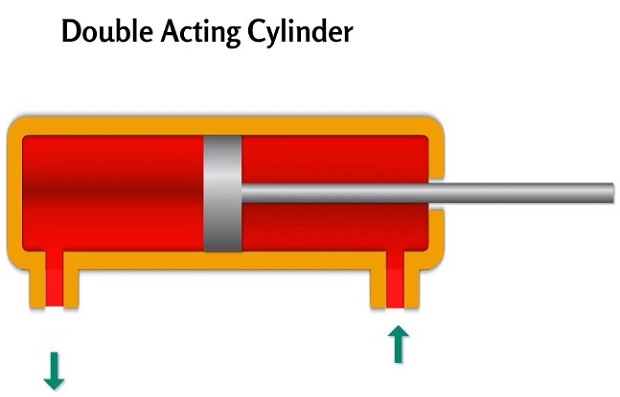

To overcome this drawback, there is

one more type of hydraulic cylinder called a double acting cylinder. Double

acting cylinders can be actuated in both directions hydraulically. As opposed to

single acting cylinders, the double acting cylinder has two ports, one for

extension and the other for retraction. You might have noticed the single rod

in the double acting cylinder. This rod covers some area on the piston where it

is connected. Due to the reduction in area, the pressure exerted on the piston

while retracting is reduced. Such cylinders are called single rod ended type. The

imbalance of pressure during the extension and retraction can be overcome by

adding another rod on the opposite side of the piston. The two rods can now

provide two equal forces in both directions. Such cylinders are called double

rod ended cylinders.

This is only one type of classification for hydraulic

cylinders. In the next article, we will talk about classification according to

the construction of hydraulic cylinders.

WEITAI has a 30 year experience in manufacturing high quality

hydraulic cylinders, both standard and customized. Leave a message, if you’re

interested in purchasing them.

Alisa Sergienko

WEITAI Marketing Department